Product Description

TECHNICAL DATA SHEET OF GRAPHITE CRUCIBLE

RE: GRAPHITE CRUCIBLE ---H.S. Code: 69031000

Composition: Carbon 99.8% Min.

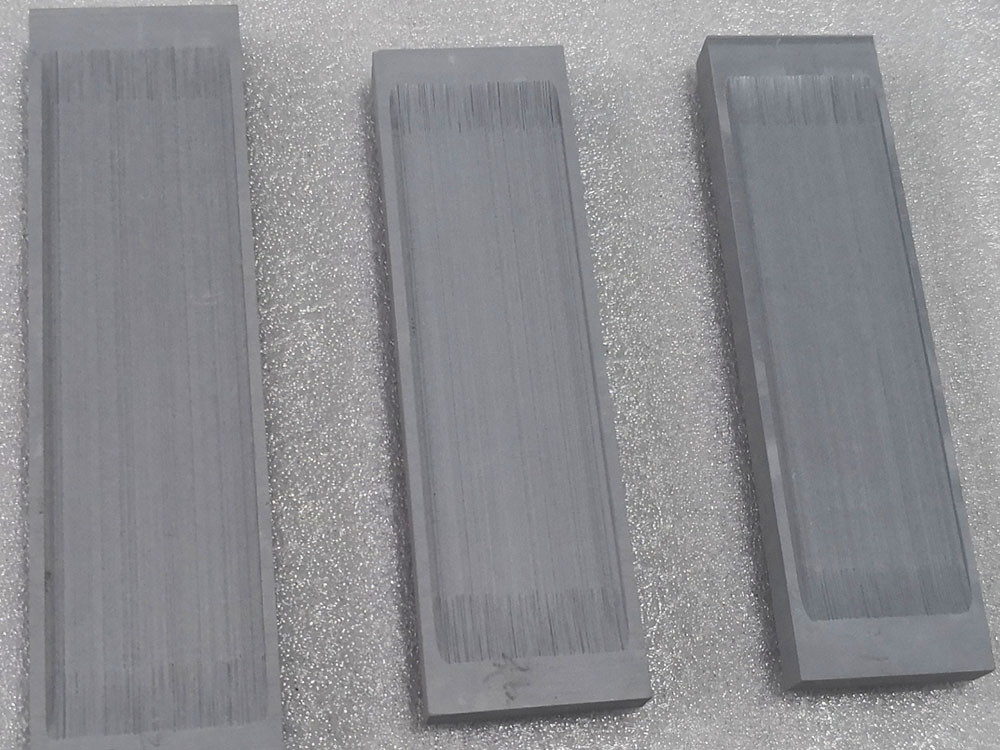

Vacuum aluminum plating is a process in which aluminum is heated to evaporation temperature in vacuum, and then deposited on the surface of the material to form a layer of aluminum film. In this process, a graphite crucible is used as a vessel for the evaporation source.

The graphite crucible has good high temperature resistance and chemical stability, and can withstand high temperature and chemical corrosion during vacuum aluminum plating. At the same time, the thermal conductivity of graphite crucible is high, which can transfer heat to aluminum effectively and make it evaporate quickly.

When using graphite crucibles for vacuum aluminizing, the following points should be noted:

• Quality and purity of graphite crucibles: select high quality, high purity graphite crucibles to avoid impurities on the aluminum plating process and coating quality.

• Pre-treatment of Crucible: before using a graphite crucible, it needs to be pre-treated, such as cleaning and drying, to remove impurities and moisture from the surface of the crucible.

• Control of process parameters of aluminum plating: the process parameters of vacuum aluminum plating, such as evaporation temperature, vacuum degree, deposition time, etc. , need to be adjusted reasonably according to the nature of the material to be plated and the requirements of the coating.

• Maintenance and replacement of crucibles: during use, graphite crucibles need to be regularly inspected and maintained, and they need to be replaced in a timely manner if damage or spalling is found on the surface of the crucible.

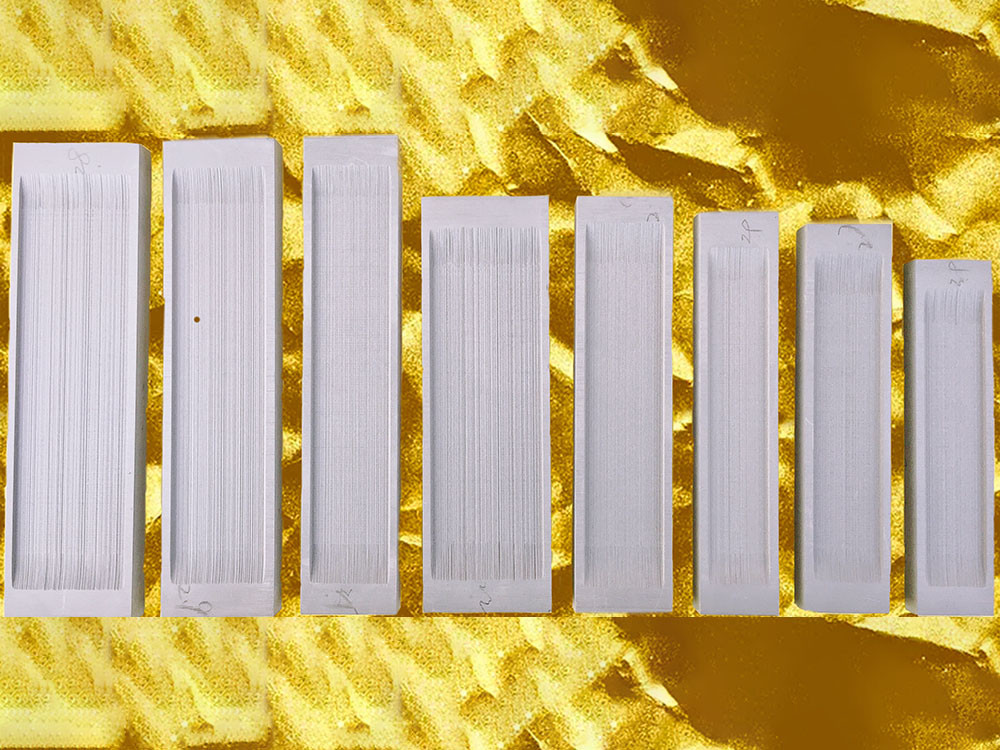

Specification :

Message

Products Recommended

Chat Online